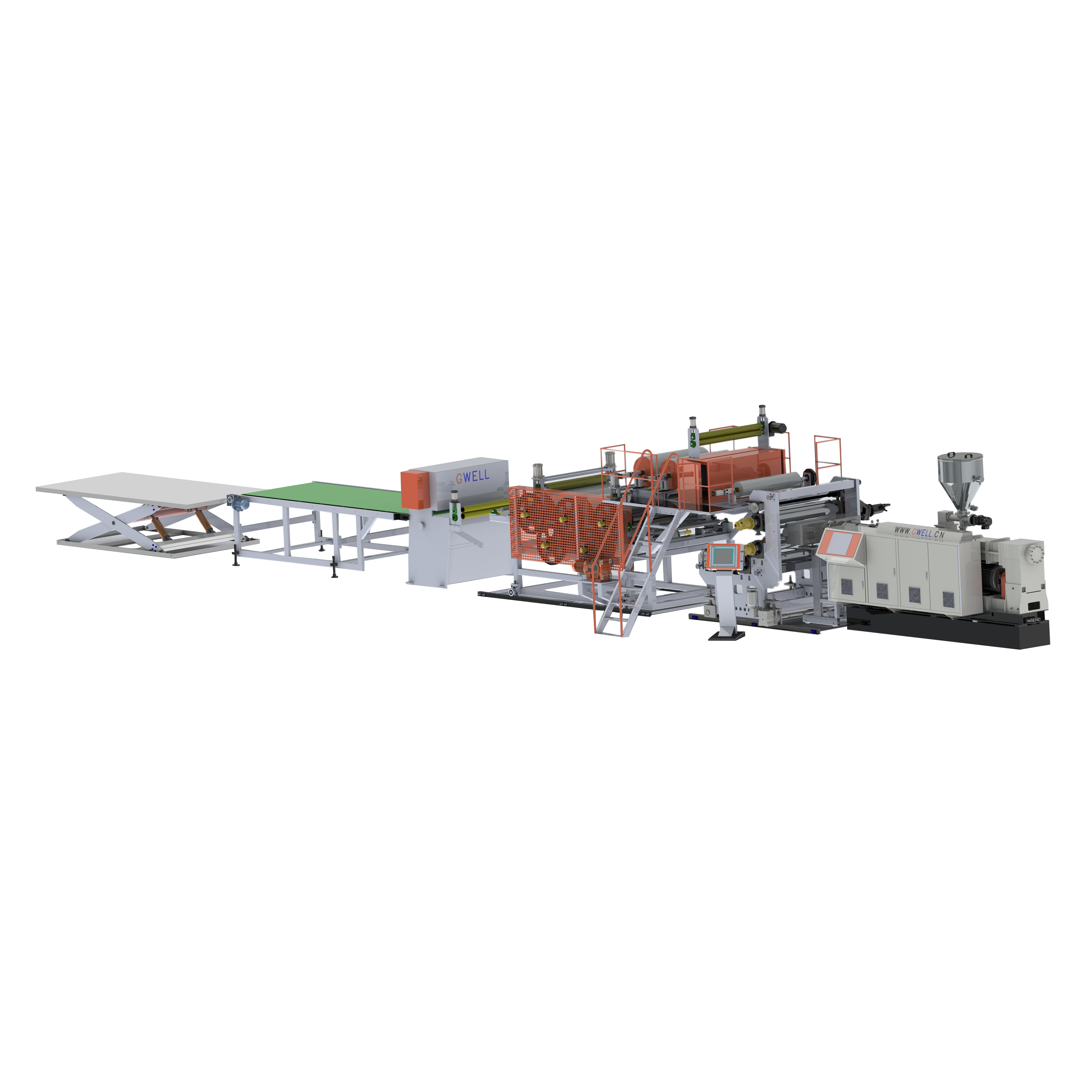

PVC marble sheet extrusion line

PVC sheet extrusion line specification

|

I.概述General |

|

||

|

1.使用条件Usage condition |

380V/3P/ 50HZ |

||

|

2.材料Suitable material |

PVC粉料 PVC powder |

||

|

3.规格Finished sheet specification |

W=1220mm, δ=0.4-5mm |

||

|

4. 产量Capacity |

500kg/h |

||

|

II.设备清单Equipment list |

|

||

|

1. 92/188锥双挤出机 92/188 Conical twin-screw extruder |

1台

1 unit |

||

|

2. 模具 Die head |

1套

1 set |

||

|

3. 热覆装置 Hot lamination system |

2套

2 sets |

||

|

4. 三辊压光机 Three-roller calender |

1台

1 unit |

||

|

5. 辊温控制器 Roller temperature controller |

1套

1 set |

||

Cooling bracket, edge trimming device |

1套

1 set |

||

Top surface protection film coatig system |

1套

1 set |

||

Doble surface corona treater |

1套

1 set |

||

|

9. 牵引机 Haul off unit |

1台

1 unit |

||

|

10. 剪板机 Guillotine cutter |

1台

1 unit |

||

|

11. 皮带输送机 Belt conveyor |

1台

1 unit |

||

|

12. 堆放台 Stacker |

1台

1 unit |

||

|

13. 电气控制 Electric control system |

全套

Complete set |

||

|

III.详细配置Detailed technical specification |

|||

|

1. GWC92/188锥双挤出机 1台 GWC92/188 conical twin-screw extruder 1 set |

|||

|

螺杆机筒Screw and barrel |

|

||

| 材质Material | 38CrMoAlA | ||

| 渗氮深度Nitrided layer thickness | 0.5-0.7mm | ||

| 螺杆硬度Screw hardness | HV≥740 | ||

| 机筒硬度 Barrel hardness | HV≥940 | ||

| 机筒加热区 Heating zones for barrel | 5 Zones | ||

| 总加热功率Total heating power | About 68KW | ||

| 加热方式Heating method | 铸铝加热 Heated by cast aluminum | ||

| 冷却方式 Cooling method | 水冷却Cooled by water | ||

|

驱动Drive |

|

||

|

电机Motor |

西门子贝得交流电机/荷兰欧瑞京 Siemens BEIDE /Holland Omec |

||

|

电机功率Motor power |

110kw |

||

|

变频器Inverter |

汇川 Inovance |

||

|

减速箱Gearbox origin |

江阴齿轮箱总厂Made in Jiangying, China |

||

|

齿轮形式 Gears type |

斜齿轮 Helical gears |

||

|

热处理 Heat treatment |

渗碳磨齿Carburized and grind |

||

|

定量喂料系统Dosing system |

|||

|

喂料斗Dosing hopper |

不锈钢 Stainless steel |

||

|

喂料电机 Dosing motor |

1.1Kw |

||

|

调速器Inverter |

汇川 Inovance |

||

|

螺杆芯部恒温油系统Constant oil temp system for screw core |

|||

|

恒温油箱加热功率Power of heating oil |

9Kw |

||

|

冷却油规格Cooling oil type |

YD132(江阴化工厂Jiangyin chemical plant) |

||

|

热交换介质Heat exchange medium |

水Water |

||

|

真空排气装置Vacuum vented device |

|

||

|

真空泵Vacuum pump |

5.5Kw |

||

|

2. 模具Die head 1套1 set 配两套模唇( equipped with 2 die lips) |

|||

|

模具结构 Die structure |

衣架式Clothes hanger type |

||

|

模具材质Die material |

优质模具钢Die steel with high quality |

||

|

模唇形式 |

推拉式模唇 Push and pull lip |

||

|

模具处理Processing of Die head |

整体调质处理,流道面镀铬抛光,抛光后铬层厚度在0.03-0.05mm

Whole part treated by thermal refining, chrome coated on the surface of flow-channel and polishing, thickness of chrome after polishing is 0.03-0.05mm |

||

|

制品宽度 Finished sheet specification |

L=1220mm, δ=0.4-5mm |

||

|

3. 热覆装置Hot lamination system |

一套 1 set |

||

|

放卷装置Unwinding unit |

|

||

|

结构形式 Structure type |

双工位结构 Double working position |

||

|

张力控制 Tension control |

磁粉制动器 Magnetic powder brake |

||

|

放卷轴规格 Size of unwinding roll |

3寸气涨轴 3 inches air swelling shaft |

||

|

纠偏器 Corrector |

配合伺服控制贴合系统 Cooperate with the servo control lamination system |

||

|

最大放卷直径 Max. unroll diameter |

500mm |

||

|

扩幅辊直径 Spreading roll diameter |

100mm,位于三辊成型机上,带扶梯,方便人员操作,钢架平台金韦尔机械制作(设计时考虑运输)。 100mm, above the calendar, with stair, can operate easily. Steel frame is made by GWELL. |

||

|

驱动功率 Drive power |

1.5KW 动力放卷,配合伺服控制贴合系统。 1.5KW cooperate with the servo control lamination system. |

||

|

4. 三辊压光机Three-roller calender |

|||

|

辊筒宽度Roller width |

1350mm |

||

|

辊筒直径Roller diameter |

1#辊 1支Ф450 花纹辊,激光雕刻,花纹与客户确认)一头进一头出水结构 2#辊 1支Ф450 镜面辊 3#辊 1支Ф450 磨砂辊 备辊 1支Ф450 镜面辊 1#roller a piece of Ф450 embossing roller (patterns will be confirmed by customer) 2#roller a piece of Ф450 mirror roller 3#roller a piece of Ф450 polished roller Spare forming roller Ф450 mirror roller |

||

|

三辊材质 Material |

合金钢 Alloy steel |

||

|

辊面粗糙度 Roller surface roughness |

Ra≤0.025 |

||

|

辊面硬度 Surface hardness |

HRC≥50 |

||

|

镀铬厚度 Chromium coated layer thickness |

≥0.08mm |

||

|

驱动 Drive |

|

||

|

驱动 Control |

汇川伺服驱动 innovance servo control |

||

|

功率 Power |

2.9KW |

||

|

传动减速箱 Gear box |

德国诺德 Germany Nord |

||

|

变频器 Inverter |

丹麦Danfoss Denmark Danfoss |

||

|

传动方式 Transmission type |

独立传动 Separate drive |

||

|

三辊间隙调整方式 Gap adjustment between rollers |

采用液压缸控制间隙及贴合压纹,液压缸加大特殊设计,带限位微调装置,有安全急停开关。 Adjusted by hydraulic device,hydraulic station increase the special design. Equipped with limited micro-adjustment and emergency stop. |

||

|

三辊形式 Calendar type |

直立式,下进上出 Vertical type, down in up out |

||

|

墙板 Side panel |

整体实心钢板 One block of solid steel |

||

|

三 辊轴承 Bearings for four rollers |

日本NSK Japan NSK |

||

|

旋转接头 Rotational joint |

GWELL |

||

|

三辊液压站 The hydraulic pressure station for rollers |

功率:4KW Power:4KW |

||

|

5. 辊温控制器 Roller temperature controller |

|||

|

冷却介质Cooling medium |

油Oil |

||

|

温控范围Temperature range |

20-180℃ |

||

|

加热功率Heating power |

4×24Kw |

||

|

热交换器Heat exchanger |

4×8m2 |

||

|

热油泵oil heating pump |

4x3Kw |

||

|

外冷却水温temperature of water supply |

<20℃ |

||

|

控制阀Control valve |

气动角座阀Pneumatic valve |

||

|

6. 冷却托架、切边装置Cooling bracket, edge cutting unit |

|||

|

长度 Length |

12m |

||

|

托辊 Supporting Rollers |

铝辊氧化处理,抛光 Aluminum rollers, oxidized, polished |

||

|

规格Type |

Ф70X1350mm |

||

|

切边装置Edge cutting unit |

2把刀,宽幅可调 2 Blade, Width is adjustable |

||

|

7. 上覆膜装置 Top surface protection film coatig |

一套 1 set |

||

|

结构形式 Structure type |

双工位结构 Double working position |

||

|

8. 电晕机 Double surface corona treater |

一套 1 set |

||

|

9. 牵引机Haul off unit |

|||

|

规格 Specification |

Φ250×1350mm |

||

|

辊筒材质 Material |

Nitrile rubber |

||

|

数量 Quantity |

1组 1 group |

||

|

驱动 Drive |

德国 Germany Gnord |

||

|

控制Control |

汇川伺服控制Inovance servo control |

||

|

胶辊压紧Roller press method |

气动控制Pneumatic control |

||

|

10.剪板机Guillotine cutter |

|

||

| 宽度Width | 1350mm | ||

| 板材计长Length calculating | 米轮编码器Meter code counter | ||

| 品牌Brand | 韩国Autonics, korea | ||

| 剪板方式Cutting type | 机械式Mechanical type | ||

| 工作方式Method | 手动或自动Manually or automatically | ||

| 11. 皮带输送机Belt conveyer | |||

| 长度Length | 3000mm | ||

| 宽度Width | 1350mm | ||

| 输送带Belt | PO Belt | ||

| 12.堆料台Product stacker | |||

| 规格Size | 1350x3000mm | ||

| 台面Surface | 不锈钢Stainless steel | ||

| 万向轮Wheel | 带刹车with braker | ||

|

13. 电气控制Electric control |

|

||

|

PLC |

SIEMENS S7-1200 |

||

|

SCREEN |

Weinview computer screen |

||

|

电柜Electricity Cabinet |

立柜Vertical type |

||

|

接触器contactor |

正泰Chnt |

||

|

变频器Inverter |

汇川 Inovance |

||

|

继电器Rely |

欧姆龙 Omron |

||

|

低压断路器Low voltage circuit breaker |

施耐德Schneider |

||

|

空气开关Air switch |

正泰CHNT |

||

|

开关,按钮Button, indicator light |

施耐德Schneider |

||

| IV、备品备件Spare parts | |||

|

螺杆拆装工具tools for screw assembling |

1套 1 set |

||

|

模具专用工具Tools special used for Die |

1套 1 set |

||

|

接触器 Contactor |

2件 2 pieces |

||

|

小断路器Small circuit breaker |

2件 2 pieces |

||

|

继电器Rely |

2个 2 units |

||

|

模具加热棒 Heating rod for Die head |

2根 2 rods |

||

|

剪板机刀片Guillotine cutter knives |

1 套 1 set |

||

|

油辊温加热棒Oil heating sticks for rollers |

2套 2 sets |

||

|

挤出机加热圈heating ring for barrels |

每区各一个Each zone 1 set |

||

Main applications of PP/PS sheet

Partner